Preventing Weld Undercut Demystified: Strategies for Success

Preventing Weld Undercut Demystified: Strategies for Success

Blog Article

Comprehending the Causes and Solutions for Undercut Welding in Metal Fabrication Processes

In the realm of steel construction procedures, the occurrence of undercut welding positions a substantial challenge that demands an extensive understanding of its reasons and feasible options. The elaborate interaction of different variables during welding procedures can lead to this undesirable phenomenon, influencing the architectural honesty and general quality of the welded joints - Preventing weld undercut. By studying the source of undercut welding and exploring reliable restorative procedures, makers can elevate the standard of their workmanship and guarantee the manufacturing of remarkable metal parts

Typical Sources Of Undercut Welding

Regularly overlooked in steel manufacture, undercut welding happens due to numerous elements that demand careful attention and expertise to be successfully minimized. Furthermore, incorrect welding strategies, such as making use of the wrong welding angle or take a trip speed, can also add to undercut development. The option of welding parameters, such as voltage, current, and wire feed rate, plays a considerable role in the incident of undercut welding.

Effect of Incorrect Welding Parameters

Unreliable welding specifications can significantly jeopardize the stability and top quality of welded joints in steel manufacture procedures. The influence of wrong welding specifications shows up in numerous means, leading to architectural weak points and flaws in the welded components. Meticulous focus to welding parameters is critical to guarantee the manufacturing of top quality welds with the wanted mechanical buildings and architectural integrity.

Impact of Improper Lantern Angle

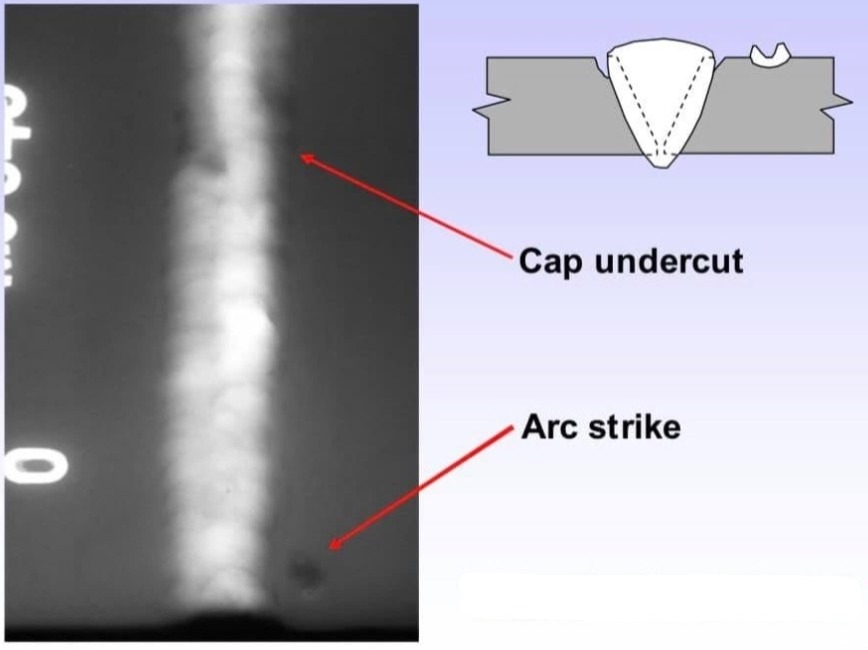

Incorrect lantern angle in welding operations can dramatically affect the top quality and stability of the final weld joints in steel fabrication procedures. The lantern angle plays an essential role in establishing the warm input and circulation throughout welding. When the lantern angle is inaccurate, problems such as undercutting can develop. Undercutting is a typical welding issue where a groove develops along the weld toe, weakening the joint and endangering its architectural integrity.

A lantern angle that is also steep can cause insufficient infiltration, insufficient combination, and increased spatter. On the various other hand, a lantern angle that is too superficial can cause too much infiltration, burn-through, and distortion of the base material. Preventing weld undercut. Proper torch angle is crucial for guaranteeing consistent weld quality, stamina, and appearance

To avoid undercutting and other issues caused by incorrect torch angles, welders must be educated to maintain the appropriate lantern angle throughout the welding process. Routine monitoring and adjustment of torch angles during welding can aid attain sound welds with marginal problems.

Duty of Inadequate Welding Methods

Another facet Discover More Here of insufficient welding methods is incorrect weld preparation. Poor cleaning of the base metals, inaccurate joint design, or inadequate edge preparation can all add to undercut welding. Moreover, poor shielding gas insurance coverage or utilizing the incorrect kind of gas can result in incomplete fusion and the development of undercut flaws.

To attend to the function of poor welding methods in metal fabrication procedures, it is essential to give comprehensive training for welders. Proper education and learning on welding specifications, joint prep work, and securing gas choice can aid avoid undercut welding and ensure high-grade welds in metal construction tasks.

Effective Solutions for Undercut Welding

Attending to undercut welding in metal construction requires implementing efficient options to improve weld quality and structural integrity. One of reference the main services to battle undercut is to adjust welding specifications such as voltage, existing, and take a trip rate to make certain appropriate warm input and combination. By fine-tuning these settings, welders can stop excessive melting of the base metal and filler product, lowering the possibility of undercut formation.

Additionally, proper joint preparation is critical in protecting against undercut. Guaranteeing tidy base steel surfaces without pollutants and utilizing the proper bevel angle can assist advertise much better weld penetration and decrease the risk of undercut - Preventing weld undercut. Using ideal welding strategies, such as oscillating the lantern or weaving, can likewise aid in distributing warm uniformly and filling the weld joint sufficiently, lessening the possibility of undercut problems

Moreover, picking the proper welding consumables, consisting of electrodes and filler steels, is essential in mitigating undercut. Utilizing materials with proper chemical compositions and mechanical homes can contribute to accomplishing audio welds with marginal undercut. Regular inspection and quality control actions my response ought to additionally be applied to find and attend to undercut issues promptly, making sure the total stability of produced steel elements.

Final Thought

To conclude, understanding the causes and solutions for undercut welding in steel manufacture procedures is essential for accomplishing premium welds. By attending to usual causes such as incorrect welding parameters, improper torch angle, and inadequate welding methods, welders can stop undercutting and ensure solid, durable welds. It is vital to take note of these factors and implement effective remedies to enhance the total welding process and last product quality.

Report this page